SERVO MOTOR & DRIVES SYSTEMS

Servo Motors:

A servo motor is a special type of motor designed for precise control of angular position, speed, and torque. Unlike standard motors, which simply run at a fixed speed when powered, a servo motor can be precisely controlled and positioned based on feedback from sensors, making them ideal for systems that require high accuracy

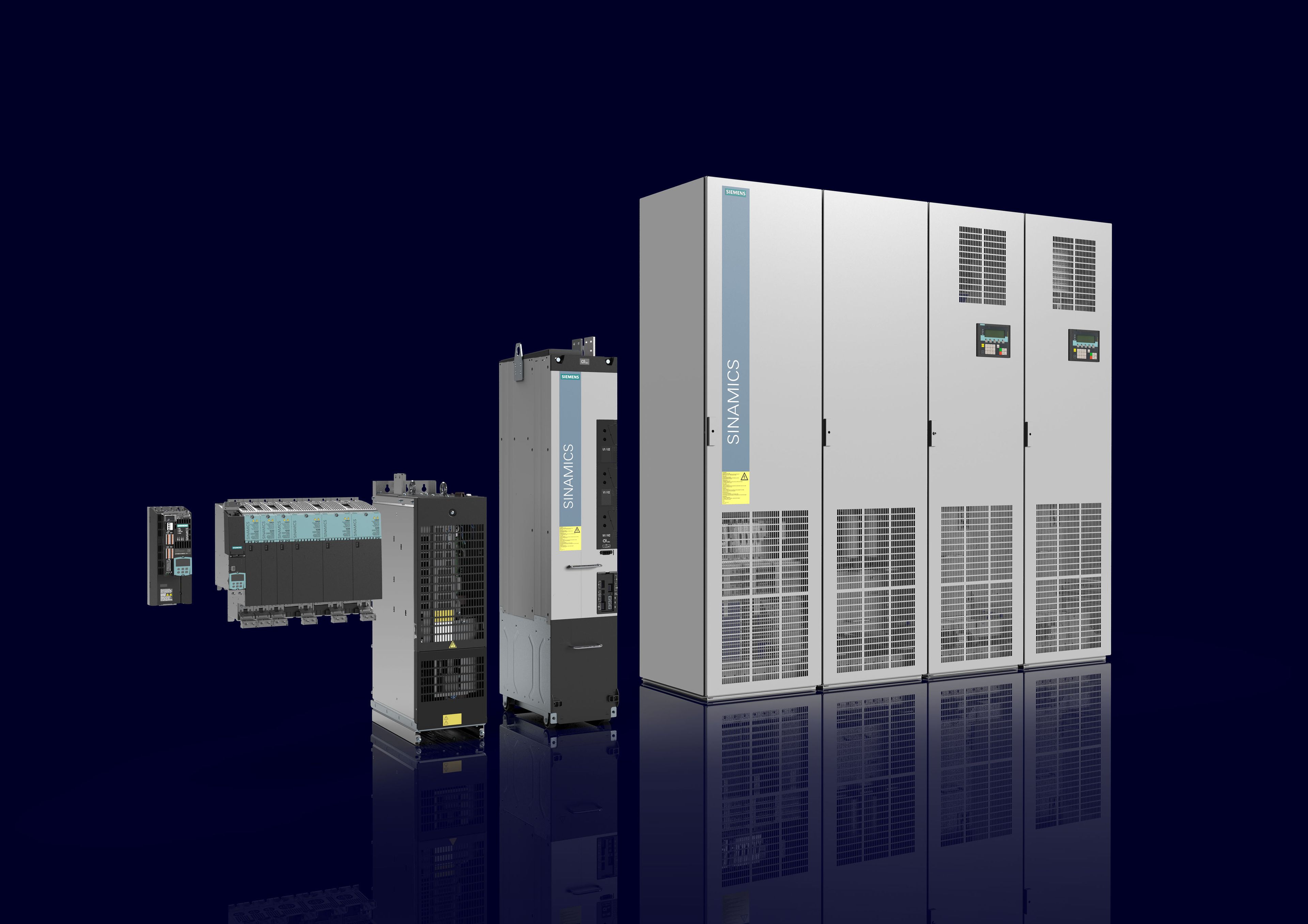

Servo Drives:

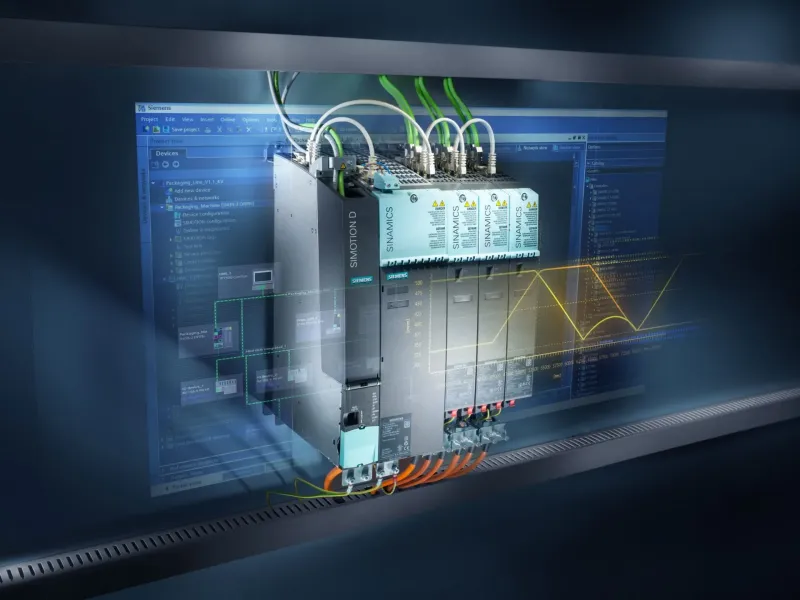

A servo drive (or servo amplifier) is an electronic device that controls the performance of a servo motor. It provides the necessary power to the motor and receives feedback from the motor’s encoder or resolver to adjust speed, position, and torque in real-time. The drive acts as the interface between the controller (e.g., PLC, motion controller, or CNC) and the motor.

Applications of Servo Motors and Drives:

Servo motors and drives are used in a wide range of applications, including but not limited to

- Packaging Machines: Servo motors provide precise control of movement in packaging machinery, ensuring high throughput and quality.

- Automated Assembly Lines: Servo systems help control conveyors, pick-and-place machines, and automated material handling systems

- Medical Devices: For precision movement in devices like prosthetics, surgical robots, and diagnostic equipment.

- Printing and Textile Machinery: For precise control of rollers, tension, and speed in printing presses or textile machines.

- Robotics: Precise control of robotic arms and end-effectors, allowing for tasks like assembly, packaging, and material handling.

- CNC Machines: For precise control of the machine’s spindle, cutting tools, and axes to achieve high-accuracy machining.